Fast, Free Quotes

Any Job Size

Next-Day Installation

Multiple Screeds One Visit

Rapid drying liquid screed for time critical construction programmes

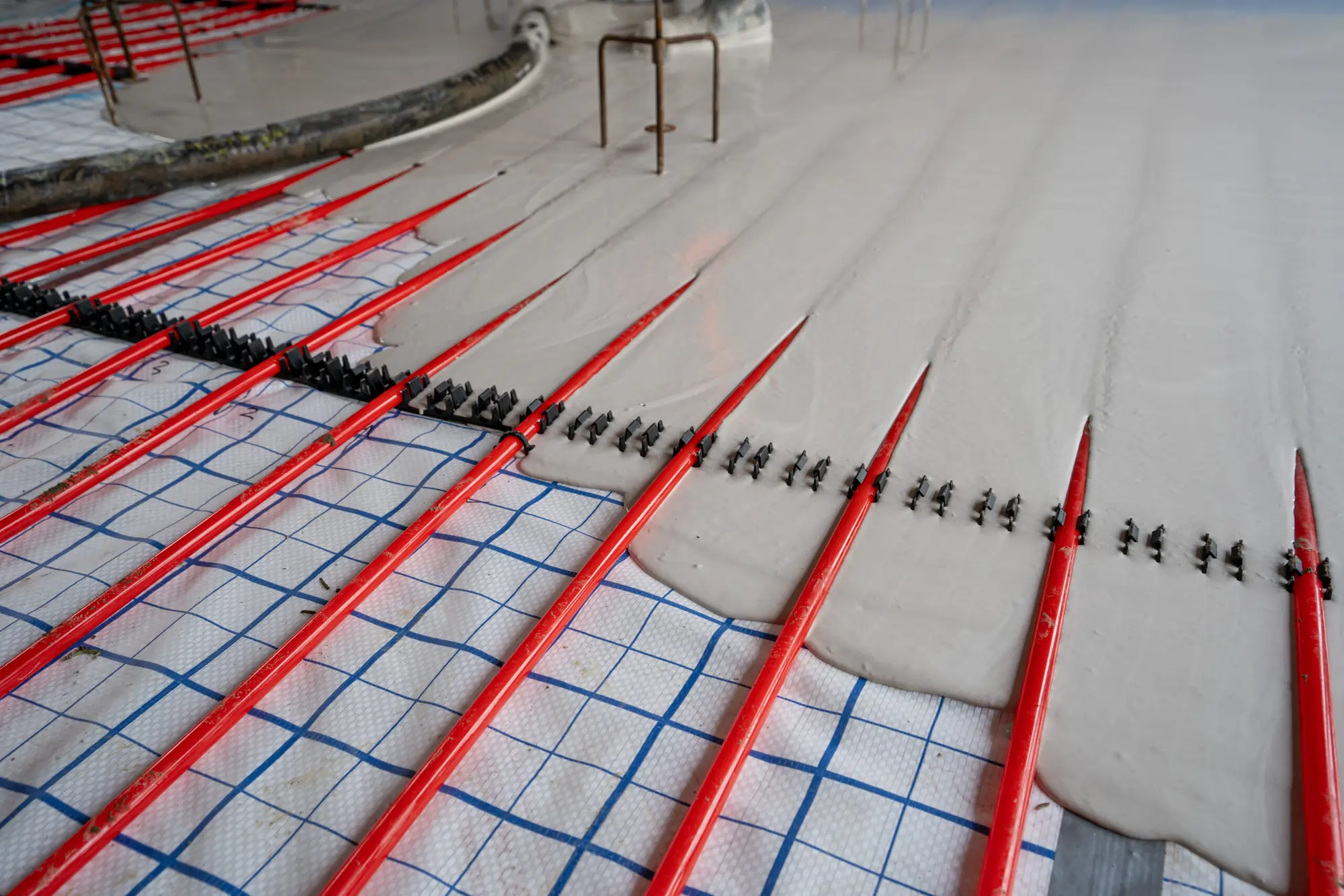

Our Fast Drying Liquid Anhydrite Screed is designed for projects where programme time is critical, delivering a smooth, level finish with significantly reduced drying times compared to standard liquid screeds.

Typical installation depths:

• From 30mm on concrete or poly membrane

• From 40mm on insulation

How it works

Getting a quote and booking your screed installation with us at Screedflo is simple and straightforward.

1. Get a quote

Enter your floor area or room sizes, select your screed type and depth, and we’ll instantly calculate the volume and email your price.

Screed Calculator

2. Preparation

Once you confirm you’d like to proceed, please ensure the area is fully prepared in line with our preparation requirements ahead of screed installation.

3. Site visit

A member of our team will then arrive to carry out a site visit. During the visit, our experienced site team will:

• Check access for 11m screed vehicle

• Confirm pumping distances

• Check floor preparation

• Answer any prep or install questions

Our screed delivery vehicle is comparable in size to a standard UK refuse lorry, allowing access to most residential and commercial sites.

4. Screed installation

Our experienced team will then arrive on the agreed date to batch the screed on site and carry out the installation.

If more screed is used on the day than originally quoted, we’ll invoice the difference. If less screed is used, we’ll arrange a refund or credit accordingly.

5. Aftercare

Once installation is complete, you should follow the aftercare guidance provided. Failure to do so may affect drying times, surface quality, and long-term performance.