Fast, Free Quotes

Any Job Size

Next-Day Installation

Multiple Screeds One Visit

Ensure the Best Performance from Your New Screed

Follow our aftercare guidance to ensure the best performance from your new screed.

0-48 HOURS

Immediately after application and until the screed has hardened, protect the surface from frost, direct sunlight, draughts and water ingress.

The environment should remain sealed for 48 hours and access restricted.

Do not cover the screed. Screed should not be cured under polythene.

48 HOURS – 7 DAYS

Light foot traffic is permitted after 48 hours, with normal site traffic and non-load-bearing partitions after 7 days.

Encourage drying after 48 hours with good ventilation and suitable temperatures.

Dehumidifiers or heaters may be used from 7 days, using a closed system.

Avoid water ingress at all times. Screedflo is not a wearing surface and should be protected from damage by other trades.

Sanding

Most screeds produce some surface laitance. After a minimum of 7 days, lightly abrade the surface to remove any loose or friable material. Use a light industrial sander with integrated dust extraction to minimise airborne dust.

Removal of laitance does not replace the flooring contractor’s responsibility for correct floor preparation prior to laying finishes.

Drying

Encourage drying after 48 hours with good ventilation, air flow and suitable temperatures. Ideally 20 degrees and 65RH.

Dehumidifiers or heaters may be used from 7 days, using a closed system to remove moisture from the atmosphere and assist drying. Avoid water ingress at all times. Screedflo is not a wearing surface and should be protected from damage by other trades.

Standard liquid screed dries at a rate of 1mm per day up to 40mm. Fast drying products can be dry in 14 days when laid at up to 50mm depth. Deeper screeds will require a longer drying period.

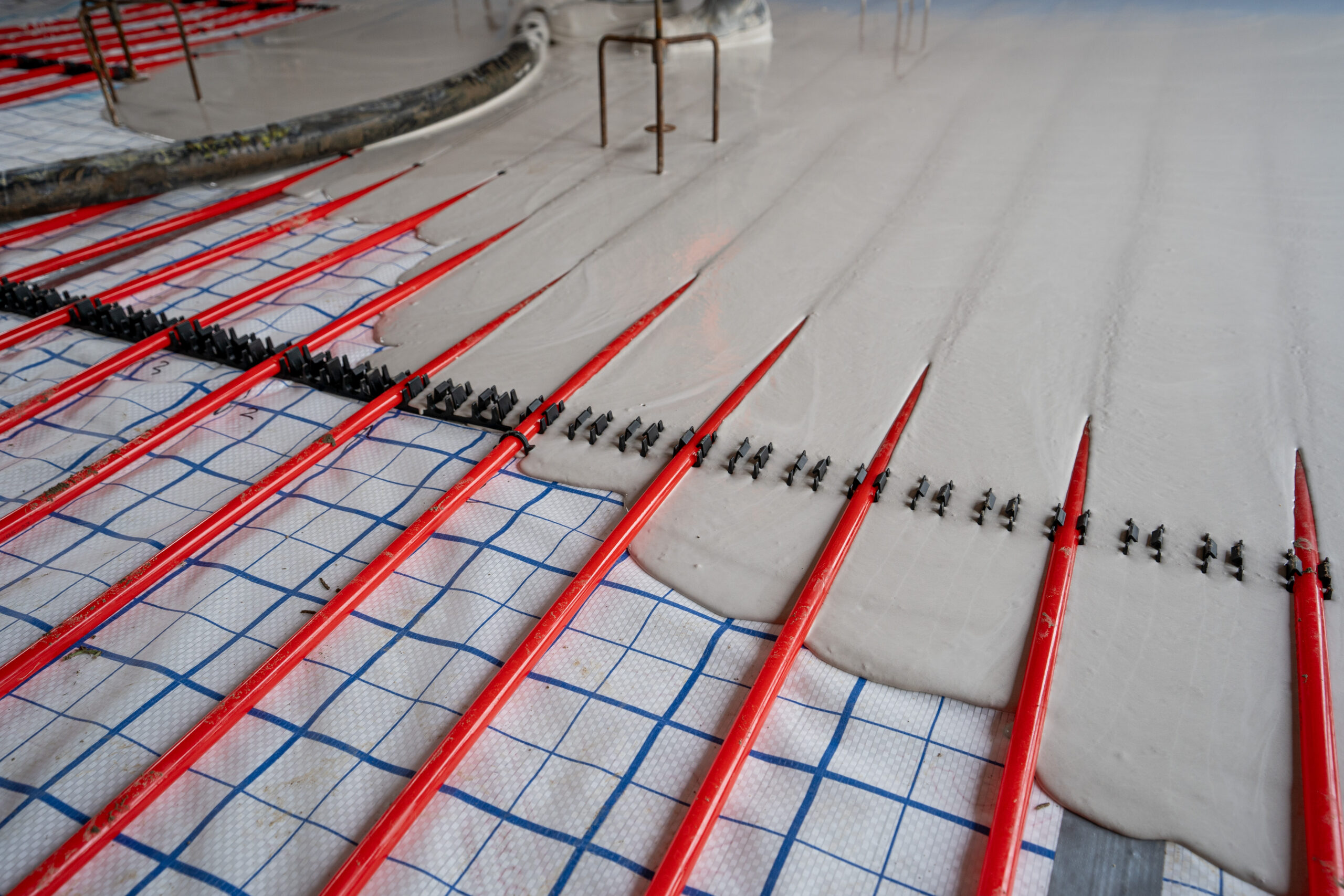

Underfloor Heating

If screed is installed with underfloor heating, the system must be properly commissioned before any floor finishes are laid, in line with BS EN 1264-4.

Heating can be turned on from 7 days after installation to help the screed dry. In good conditions, a 50mm screed may be ready for floor coverings after around 28 days.

The heating must be switched off and allowed to cool for at least 48 hours before the screed moisture is tested. Not following this process may lead to floor finish failure.

Floor Finishes

In accordance with the relevant national standards, it is the responsibility of the flooring contractor to ensure the screed is sufficiently dry, properly prepared, and suitably keyed prior to the installation of floor coverings.

As a general guide, the screed surface should be mechanically sanded to remove any loose or friable laitance and to ensure it is free from debris or contamination that could affect adhesion.

This may include paint, plaster, mortar, mud, or other materials introduced during normal site activities.